Imagine if you could print out three-dimensional objects straight from a printer in your home. When I was a kid in primary school, I thought it would be awesome if I could print pizzas out of my InkJet.

That’s not where this article is heading, but it’s an interesting thought—printing out three-dimensional objects, that is. It sounds like borderline science-fiction, and for a long time, it was.

Not anymore.

What Does a 3D Printer Do?

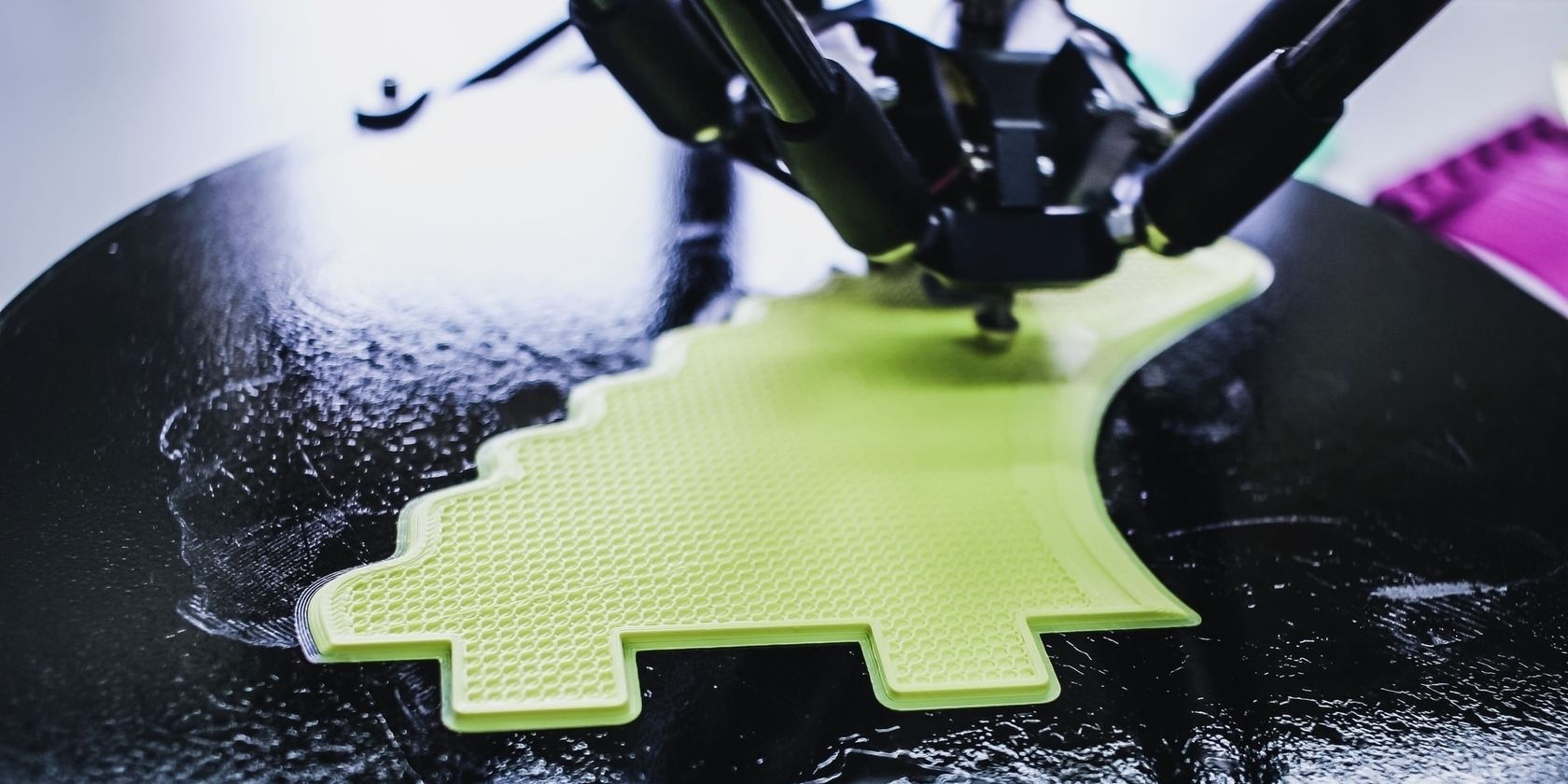

The process is, unsurprisingly, called 3D printing. Like traditional printing, which takes a blank piece of paper and creates two-dimensional images and text out of seemingly nowhere, 3D printing creates fully realized objects out of nothing. It’s a fascinating procedure that can be useful in a number of fields.

3D printing technology has been around for close to 30 years. But back then, it was still in the realm of high-tech that few had access to—mainly corporations and major movie studios. It took the industry two more decades to get 3D printers to the average consumers.

But 3D printing didn’t have a linear journey from its creation to now, and it wasn’t as complete and accessible of a process as it is today.

A Brief History of 3D Printing

Back in 1986, a guy named Charles W. Hull filed a patent for stereolithography, which became the first known method of creating 3D objects out of thin air. The invention of this method ushered in a new age of machining processes.

Whereas most objects are built using a subtractive process (i.e., whittling, drilling, carving, slicing, etc.), 3D printing uses an additive process (i.e., adding material).

Despite the massive technological advancements that made 3D printing more accessible to the public, 3D printers are still pretty expensive. While you can get an ink printer that creates decent results for less than $50, a new 3D printer costs anywhere from $400 for low-capacity hobbyist printers to over $4,000 for professional printers.

Fortunately, you don’t have to justify purchasing a 3D printer to your wallet. There are companies all over the world that provide 3D printing services at various price points. Whether you’re printing parts for a mechanical project you’re working on or simply want a 3D figure or decoration for your home or office, they’ll print it for you.

Nearly all forms of 3D printing require an STL file. An STL file is a specific format of 3D model that allows 3D printers to conveniently and effectively slice up the object into the individual layers used in the actual printing. Most STL files are first created in a computer-aided design (CAD) program and then converted.

How Does a 3D Printer Work?

Just like regular printers use different techniques for printing, so do 3D printers. There are many different types of 3D printing techniques, but here are some of the most common.

Stereolithography (SLA)

SLA is the first 3D printing technique that was developed. It creates objects out of thin air by printing layers and layers of a particular photopolymer on top of itself. The material begins as a liquid and changes to a solid when hit by a concentrated ultraviolet light beam.

Digital Light Processing (DLP)

DLP is similar to stereolithography in that it uses light to harden a liquid into a solid. However, in digital light processing, the object starts as a vat of full liquid.

A portion of the liquid is exposed to light, which hardens, then the build plate is lowered by a small amount. Another shot of light hardens more of the liquid, and this process repeats. Any leftover liquid is drained, leaving behind a solid model.

Selective Laser Sintering (SLS)

SLS uses a high-power laser to fuse material particles (e.g., plastic, glass, ceramic, and metal) into a mass that takes the desired three-dimensional shape.

Electron Beam Melting (EBM)

EBM is a 3D printing process used for metal parts. The process takes place in a vacuum and begins by spreading down a layer of metal powder (most often titanium). An electron beam then melts the powder into a solid layer. Objects created this way are surprisingly dense and strong.

Multi-Jet Modeling (MJM)

MJM works similarly to modern InkJet printers. It spreads a layer of resin powder and then sprays a colored binding glue-like substance that hardens the powder into a single layer. Multi-jet modeling is extremely useful because it is fast and supports colored printing.

Fused Deposition Modeling (FDM)

FDM uses a heated extrusion nozzle that melts a material (e.g., plastic) as it comes out. The nozzle can move around both horizontally and vertically through computer-aided controls. As the material exits the nozzle, it hardens almost immediately.

Benefits of 3D Printing

3D printers have an undeniable advantage for any type of work that requires custom parts, whether it’s commercial or personal. In addition to the upfront investment in the printer and the materials, operating 3D printing requires a technical background in reliable knowledge in design.

Design and Decoration

After all, what good is a custom-parts-making machine if you can’t create custom 3D models in digital form?

Design-related work is made much faster and easier with 3D printers.

Designers can take concepts and ideas and quickly produce a working three-dimensional representation—called rapid prototyping. Then, as the design evolves, each iteration can be prototyped almost immediately.

Manufacturing

Companies can also benefit by using 3D printers in creating their final products, not just prototypes. The nature of 3D printing allows for ease of customization.

Typical assembly lines require the different pieces of an object to fit together in a specific way, or else the line fails. With a 3D printer, personal customizations are made in the STL file—the printer doesn’t need to be altered.

Healthcare

And the level of detail that can be achieved through 3D printing is phenomenal. The accuracy of a 3D printer can go so far as 4-micron resolution. That’s thinner than a single human hair. That makes it a great tool for use in the medical field.

3D printers can be used to print specialty medical equipment, prosthetics, and essential organ parts such as heart valves. Additionally, 3D printing plays a role in biomedical engineering, pioneering the quest to 3D printing organs and live tissues in a process known as bioprinting.

The 3D Printing Revolution Is Here

3D printing is proving itself to be a world-changing tech. The limits with 3D printing are as far and wide as your imagination. If you can design it in 3D software, you can turn it into a reality, whether it’s for a hobby, to fix a mechanical problem, or save someone’s life.

About The Author